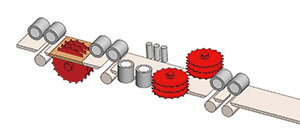

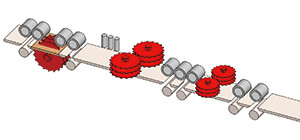

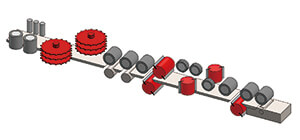

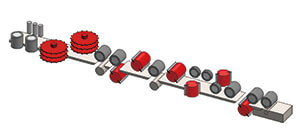

titan Slicermac Splitting Planer/Moulder

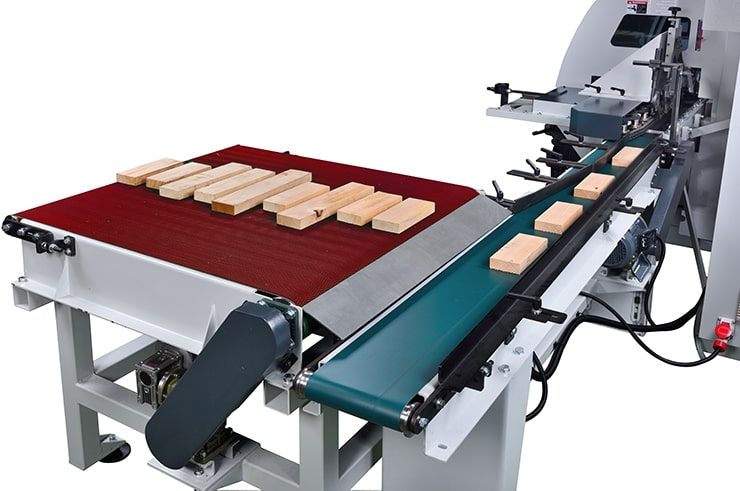

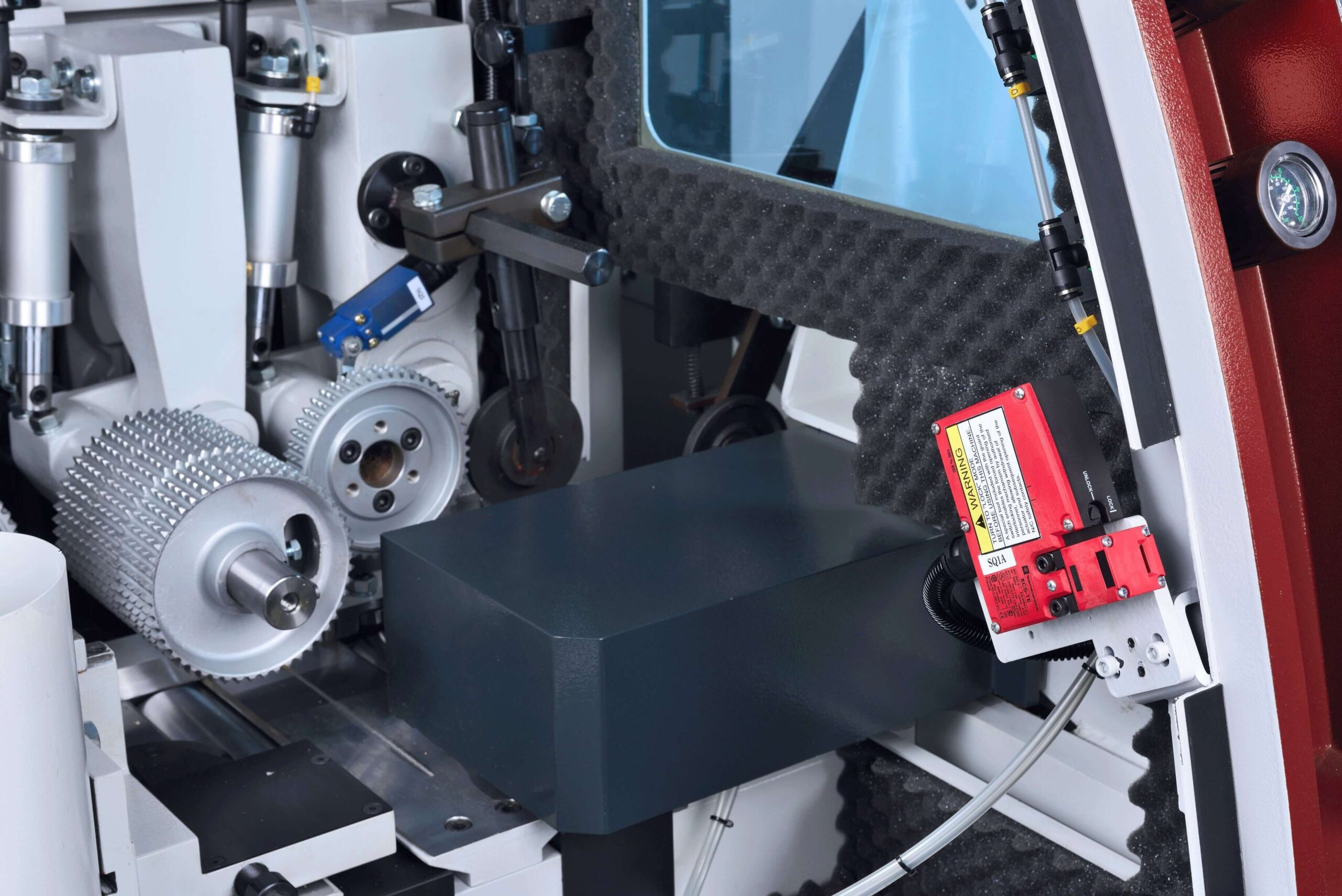

The Titan Slicermac is designed and engineered to process horizontally sawn material with flexibility in mind. With feed speed up to 24m/min and is equipped with 6,000 RPM spindles to meet the high speed requirements. Its rigid cast iron construction allows for consistent, accurate and deformation-free machining.

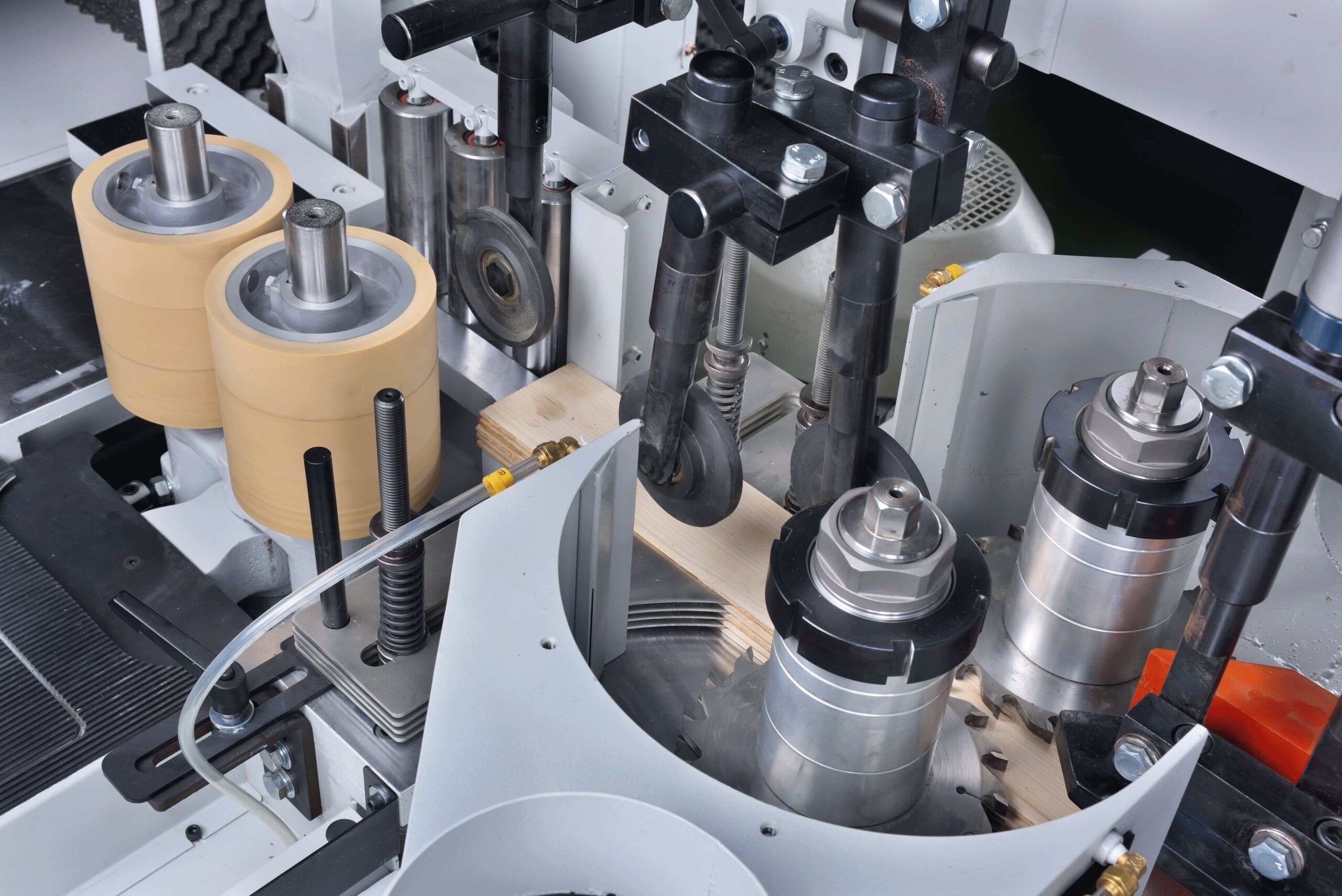

Besides its 4-side moulding configuration, two slicing units ensure clean and precise slicing operations. With the Titan Slicermac you get the speed and versatility to significantly boost your productivity.

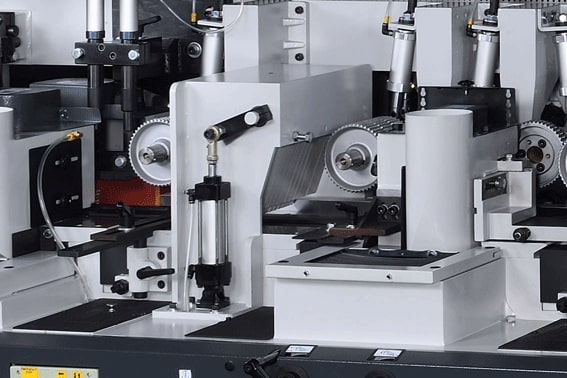

Side pressure rollers

slicing unit

A Wide Range of Spindle Configurations (other configurations available on request)

SPECIFICATIONS | Slicermac Models 223-823 |

Working width for moulding: | 230 mm |

Working height for moulding: | 10 - 150 mm |

Working width: | 200 mm |

Working height: | 100 mm |

Number of spindles: | 2 – 8 (Min-Max) |

Basic motor capacity per spindle: | 5.5 KW / 7.5 HP |

Basic motor capacity of feed: | 4 KW / 5 HP / Inverter |

Spindle speed: | 6000 RPM for Moulding Spindle |

4000 RPM for Multiple Rip Saw Spindle | |

Spindle diameter: | 40 mm for Moulding Spindle |

50 mm for Multiple Rip Saw Spindle | |

Tool cutting circle: (first bottom spindles) | 125 - 160 mm (Min-Max) |

Max. saw blade cutting circle (1st slicing unit): | 250 mm |

Max. saw blade cutting circle (2nd slicing unit): | 300 mm |

Tool cutting circle: (top horizontal spindles) | 112- 200 mm (Min-Max) |

Tool cutting circle: (bottom horizontal spindles) | 112- 200 mm (Min-Max) |

Infinitely variable feeding speed controlled by VFD Device: | 6 - 24 m/min |

Feed roller diameter: | 140 mm |

Feed roller width: | 50 mm |

Max. pneumatic pressure for feed rollers: | 6 kg/cm² (87psi) |

Adjustment range for infeed table and edge of jointing fence: | 10 mm |

Adjustment range of vertical spindles (axial): | 30 mm |

Adjustment range of horizontal spindles (axial): | 20 mm |

Adjustment range of vertical spindles for slicing units (axial): | 5 mm |

Length of straightening table: | 2 Metres |

Other Recommendations:

[Photos are for reference only. Machine models may vary from photos shown]