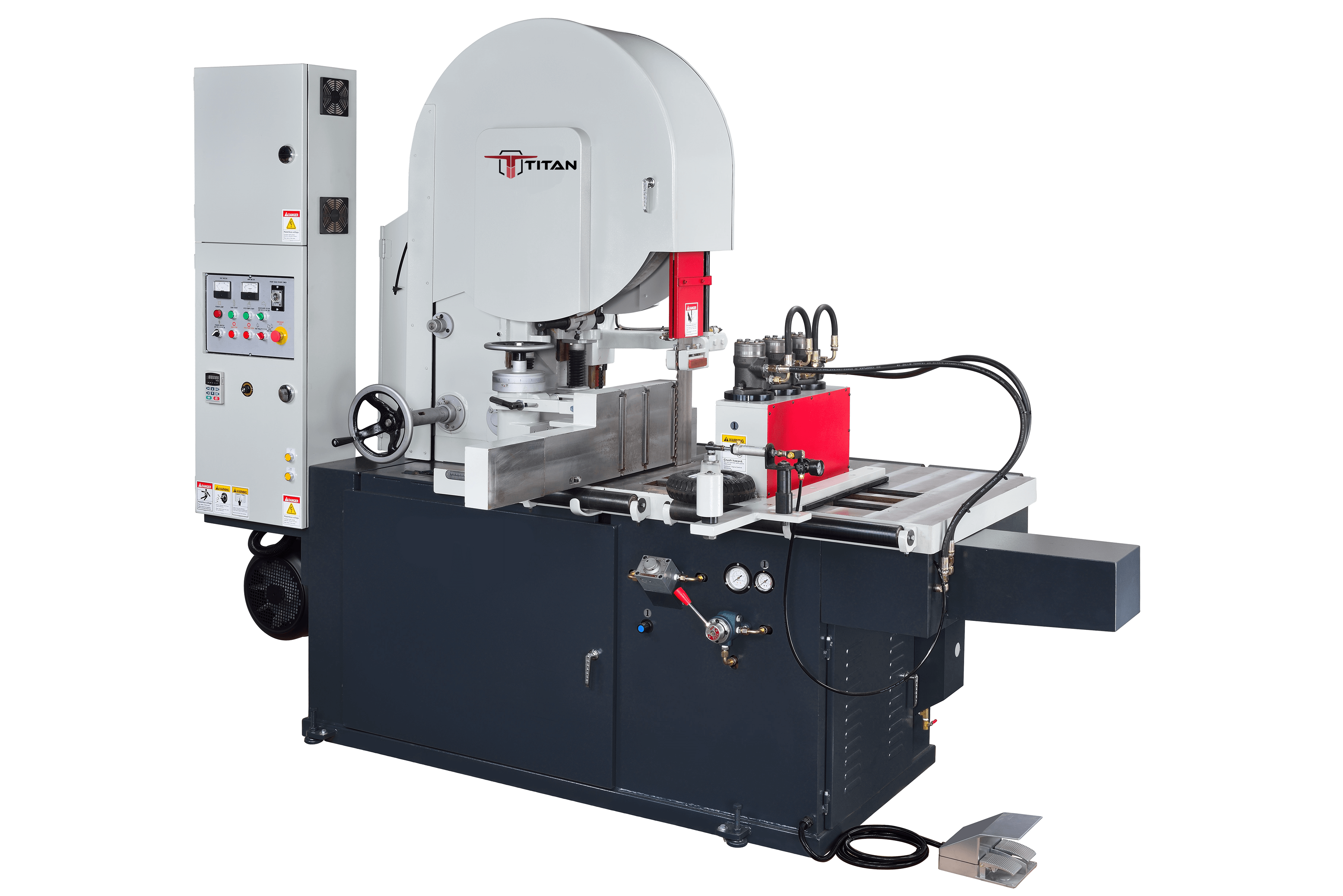

titan Platinum moulder

The Titan Platinum Moulders are solid machines designed to provide fast set up times and the highest accuracy. Suitable for heavy joinery or medium sawmilling applications in both soft and hardwoods.

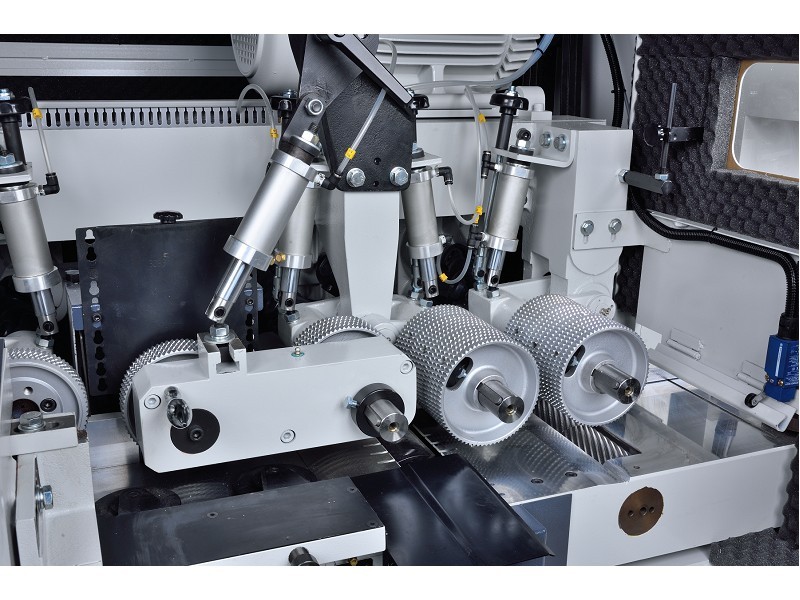

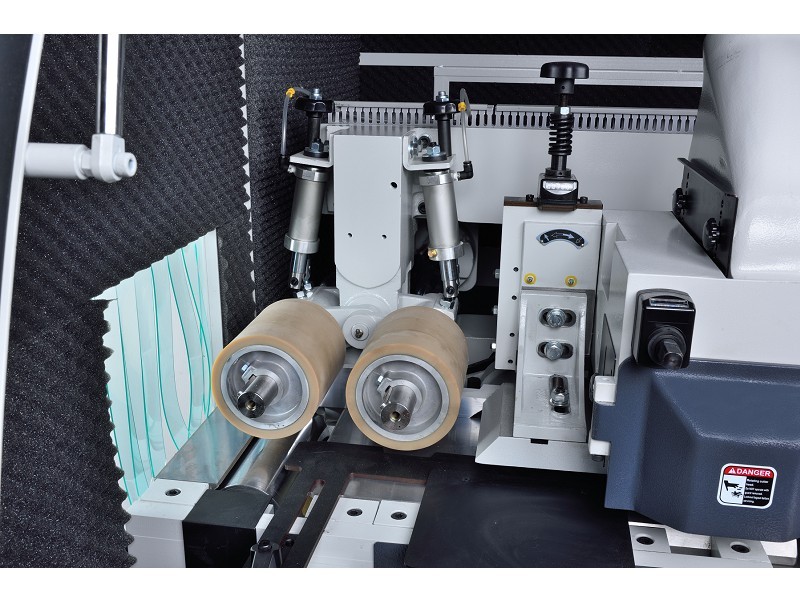

Powered bottom infeed roller

auxiliary feed roller

Accurate Pressure Display

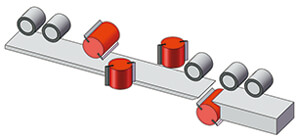

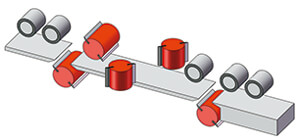

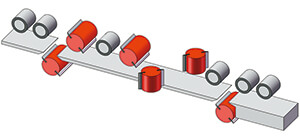

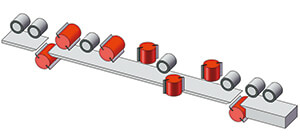

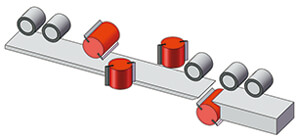

A Wide Range of Spindle Configurations (other configurations available on request)

SPECIFICATIONS | Platinum Models | Available Options |

Working Width (at a tool cutting circle of 140mm) | 15-230mm (0.59"-9.1") | to 260mm, 300mm or 330mm (10.2", 12" or 13" optional) |

Working Height (at a tool cutting circle of 163mm) | 10-150mm (0.39"-6") | to 6mm & to 200mm or 250mm (to 1/4" & to 8" or 10") - optional |

Number of Spindles, min-max | 1 to 8 Heads / Spindles | All different types of Spindle Configurations - optional |

Universal Last Head or Rip Saw Attachment | Available - option |

|

Basic motor Capacity of Feed - VFD - Variable Frequency Drive | 2.2KW / 5HP | to 18.5KW/25HP - optional |

Feed speed, infinitely variable by frequency driven motor | 6 - 30 m/min (20 - 100 fpm) | 7200 RPM or 8000 RPM |

Basic Motor Capacity per Spindle | 7.5KW / 10HP Vert & 11KW / 15HP Hor. | 50mm, 1 1/2", 1 13/16" |

Spindle Speed | 6000 RPM |

|

Spindle Diameter | 40mm (1.6") |

|

Tool cutting circle, first bottom spindle, min-max | 125-160mm (4.9"-6.3") |

|

Tool cutting circle, vertical spindles, left, min-max | 112-200mm (4.4"-7.9") |

|

Tool cutting circle, vertical spindles, right, min-max | 112-200mm (4.4"-7.9") |

|

Tool cutting circle, horizontal spindles, top, min-max | 112-200mm (4.4"-7.9") |

|

Tool cutting circle, horizontal spindles, bottom, min-max | 112-200mm (4.4"-7.9") |

|

Feed roller diameter | 140mm (5.5") |

|

Top Feed roller width - each roll with multiples on all Top shafts | 3 x 50mm (2") |

|

Bottom Feed Roll Width | Full Width |

|

Pneumatic pressure for feed rollers, max | 6 bar (85psi) |

|

Adjustment range for Infeed Table | 10mm (0.4") |

|

Adjustment range for Edge-jointing Fence | 10mm (0.4") |

|

Adjustment range of Vertical Spindles (axial) | 40mm (1.58") | 100mm (4") - optional with set works if desired |

Adjustment range of Horizontal Spindles (axial) | 20mm (0.79") |

|

Length of the straightening table | 2M (78.7") | 1.5M, 2.5M or 3M (58", 98" or 120" - optional) |

Diameter of Dust Hood for vertical spindle | 125mm (5") |

|

Diameter of Dust Hood for horizontal spindle | 125mm (5") |

|

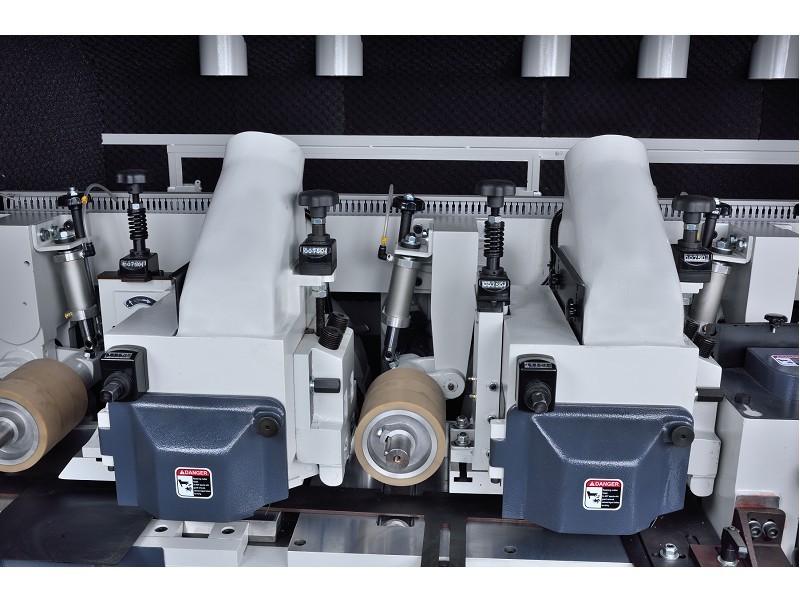

Chainless Cardan Shaft Feed System w/ HD Gearboxes | Standard |

|

Motorized vertical adjustment of feed beam | Standard |

|

Lateral pressure roller opposite first right spindle | Spring Tensioned Standard | Pneumatic Tensioned - optional |

Sectional Radial Lift - Linage Style Top Head Chipbreakers | Spring Tensioned Standard | Pneumatic Tensioned - optional |

Mechanical digital readouts for the pressure shoes & hold-down unit | Standard | Metric or Inch Readouts |

Mechanical Digital Readouts on all Spindle Axis | Single - Std. | Dual on Near Side, & Tops - Radial Readouts & Quik Set - optional |

Central location of all lubrication points at the front of the machine | Standard |

|

Auto Table Lube System | Standard |

|

Full sound and safety enclosure | Standard |

|

Other Recommendations:

[Photos are for reference only. Machine models may vary from photos shown]